Carnot’s extensive experience in compressed air includes:

- Troubleshooting pneumatic related production problems

- Improving production rates and compressed air system reliability

- Energy efficiency

- Compressed air surveys

- Design and project management of equipment upgrades

Energy efficiency (EE) has a central role in tackling climate change. It is often referred to as the “First Fuel” as it is the fuel you do not have to use. EE initiatives are often the most cost-effective way to reduce greenhouse gas emissions. They allow energy delivery systems to be smaller and cheaper. The savings in infrastructure costs pay for the EE works, let alone the actual energy savings value.

This article seeks to:

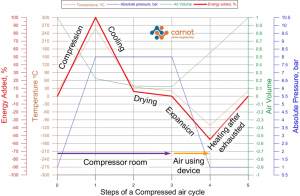

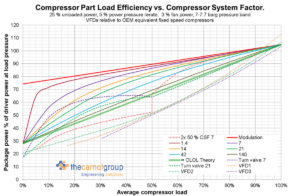

- Better inform the discussion about the efficiency of a Compressed Air System(CAS)

- Show how calculating system efficiency using an “electrical and thermal energy balance method” is flawed.

- Provide a more informed description of what affects the conversion efficiency of a CAS

This article should guide those calculating the economics of compressed air energy efficiency projects away from using potentially flawed “rules of thumb” to seeking out and collecting well-informed data.

The guide is for operators of compressed air systems, maintenance staff, production managers and other technical staff who wish to optimise the efficiency of their compressed air systems without spending significant capital. This guide sets out low capital cost, simple-to-do actions that can help you to:

- free up system capacity to better meet your compressed air demands

- save money by avoiding or delaying buying a new compressor

- complement your efforts to ensure system reliability

- reduce your electricity bills

This compressed air guide, located on the website of the NSW Department of Planning, Industry and Environment (formerly Office of Environment and Heritage), was published in 2017.

- Provide insight into the state of a compressed air system

- Help identify low capital cost projects to improve the efficiency of compressed air systems

- Help assess the merits of supply side and demand side compressed air efficiency projects

This article, written by The Carnot Group’s Murray Nottle, was published in Compressed Air Best Practices (CABP) magazine and is located on the magazine’s website.

CABP is a USA based compressed air trade magazine that is published monthly as a hard copy for North American subscribers and on line for a global audience.

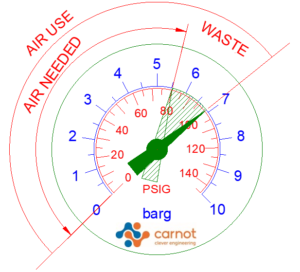

Managing Pressure Regulator Artificial Demand

Pressure regulators are used everywhere compressed air is used. These simple devices, essential for safe and steady equipment operation, can be a big waste of compressed air.

This two part article, written by The Carnot Group’s Murray Nottle, was published in Compressed Air Best Practices (CABP) magazine and is located on the magazine’s website.

CABP is a USA based compressed air trade magazine that is published monthly as a hard copy for North American subscribers and on line for a global audience.

With proper regulator selection, installation and setting management you can save compressed air and lower system pressures.

We take great pride in the work we produce, the service we provide and the results we deliver. We form strong relationships with clients based upon mutual respect, their success is our success.